about the

about the

industry

industry

The mission of the fertilizer industry is to feed the world. Because without modern-day fertilizer, the world as we know it would not exist. Farmers around the globe can meet the demands of feeding a growing population, but only because of fertilizer. In fact, half of all food consumed today is only able to be grown because of fertilizer.

This report tracks industry performance on environmental, economic, and social indicators across the entire value chain. Now in its fifth year, the State of the Fertilizer Industry Report seeks to measure and evaluate industry efforts to identify successes and target areas for improvement.

Scroll for more info about the fertilizer industry’s efforts to sustainably produce, transport, and apply fertilizer to farms across the United States.

Industry Value Chain

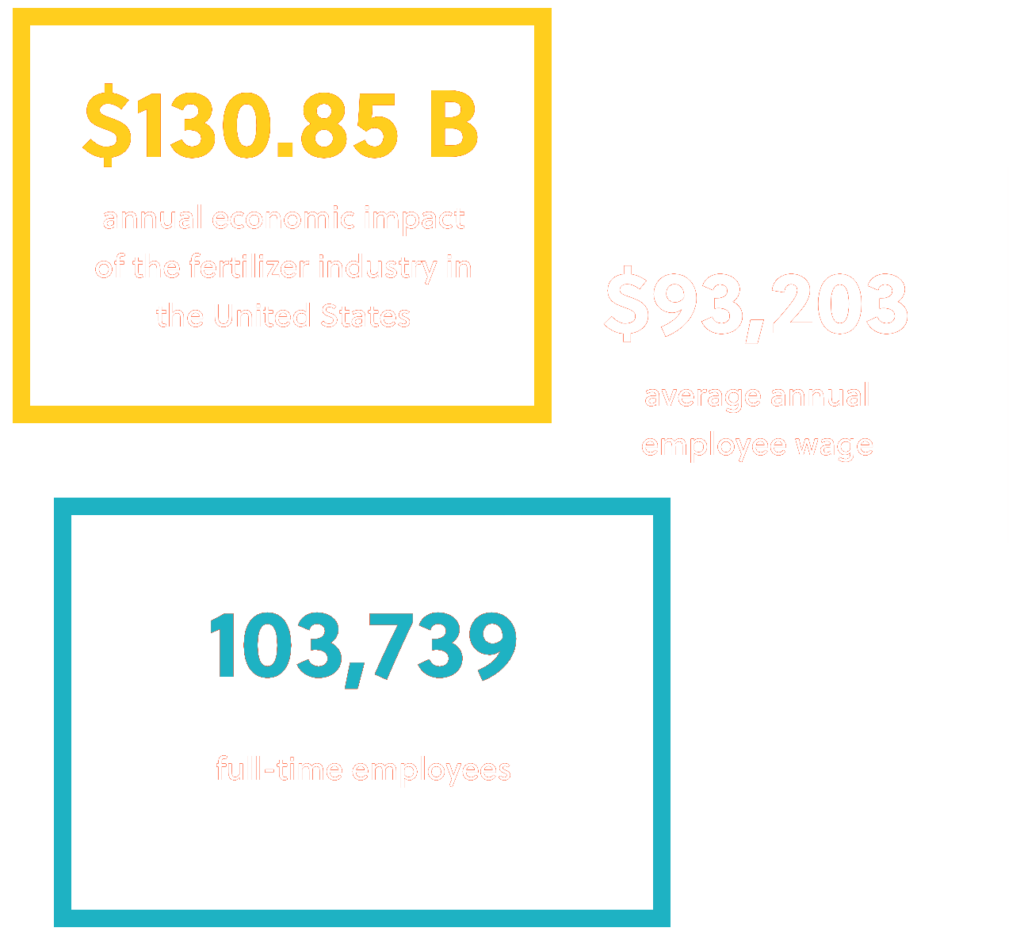

The United States is the world’s fourth largest producer of nitrogen fertilizers and the second largest producer of phosphate. The fertilizer industry is made up of companies that represent the entire supply chain from production to distribution to retail, all working together to deliver fertilizer to farmers in a safe, timely, and sustainable manner.

So what is fertilizer anyway?

Plants, just like humans, need nutrients to survive and reach their full nutritional potential. Three of these elements – carbon, hydrogen, and oxygen – are obtained through the air and water. But there are 14 elements plants need to grow, and these are the elements in modern-day fertilizers. These elements are grouped into three categories: macronutrients, secondary nutrients, and micronutrients. All must be present in soil in the right form and at the right rate, time, and place to grow healthy crops.

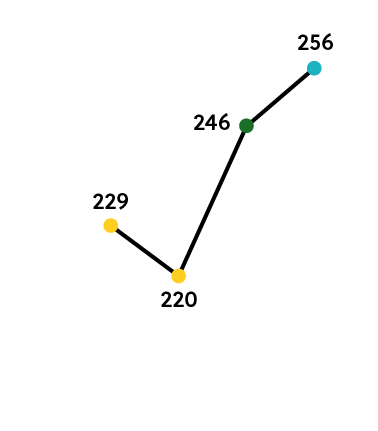

This report includes data from 34 companies. Fifteen of these companies manufacture fertilizer and account for 91 percent of total nitrogen, phosphate, and potash production capacity in the United States. This report gathers data across the entire value chain, with an additional 19 participating companies serving as retailers, wholesalers, and distribution companies. This represents 32 percent of the U.S. fertilizer retail industry.

Not all participating companies submit data for each metric. A full data set and the number of companies reporting on each metric is in the sustainability performance indicators at the end of this report.

Industry Value Chain

The United States is the world’s fourth largest producer of nitrogen fertilizers and the second largest producer of phosphate. The fertilizer industry is made up of companies that represent the entire supply chain from production to distribution to retail, all working together to deliver fertilizer to farmers in a safe, timely, and sustainable manner.

So what is fertilizer anyway?

Plants, just like humans, need nutrients to survive and reach their full nutritional potential. Three of these elements – carbon, hydrogen, and oxygen – are obtained through the air and water. But there are 14 elements plants need to grow, and these are the elements in modern-day fertilizers. These elements are grouped into three categories: macronutrients, secondary nutrients, and micronutrients. All must be present in soil in the right form and at the right rate, time, and place to grow healthy crops.

Macronutrients make up the majority of all fertilizer produced. These are essential for plant growth.

Secondary nutrients, while still essential for plant growth, are typically needed in smaller quantities than macronutrients.

This report includes data from 34 companies. Fifteen of these companies manufacture fertilizer and account for 91 percent of total nitrogen, phosphate, and potash production capacity in the United States. This report gathers data across the entire value chain, with an additional 19 participating companies serving as retailers, wholesalers, and distribution companies. This represents 32 percent of the U.S. fertilizer retail industry.

Not all participating companies submit data for each metric. A full data set and the number of companies reporting on each metric is in the sustainability performance indicators at the end of this report.

Company Participants

Company Participants

Fertilizer and the United Nations Sustainable Development Goals

The United Nations’ 17 Sustainable Development Goals (SDGs) involve the work of governments, business, and citizens to end poverty and promote prosperity while protecting the planet. TFI and our members are actively contributing to the following SDGs.

#2 Zero Hunger

The fertilizer industry supplies the nutrients needed to grow the crops that feed the world.

#6 Clean Water and Sanitation

Sustainable water management practices and land reclamation are in place during fertilizer production, and on the farm, fertilizer best management practice awareness, research, and implementation is a priority to reduce environmental loss. The adoption of 4R fertilizer management practices is a priority to improving water quality.

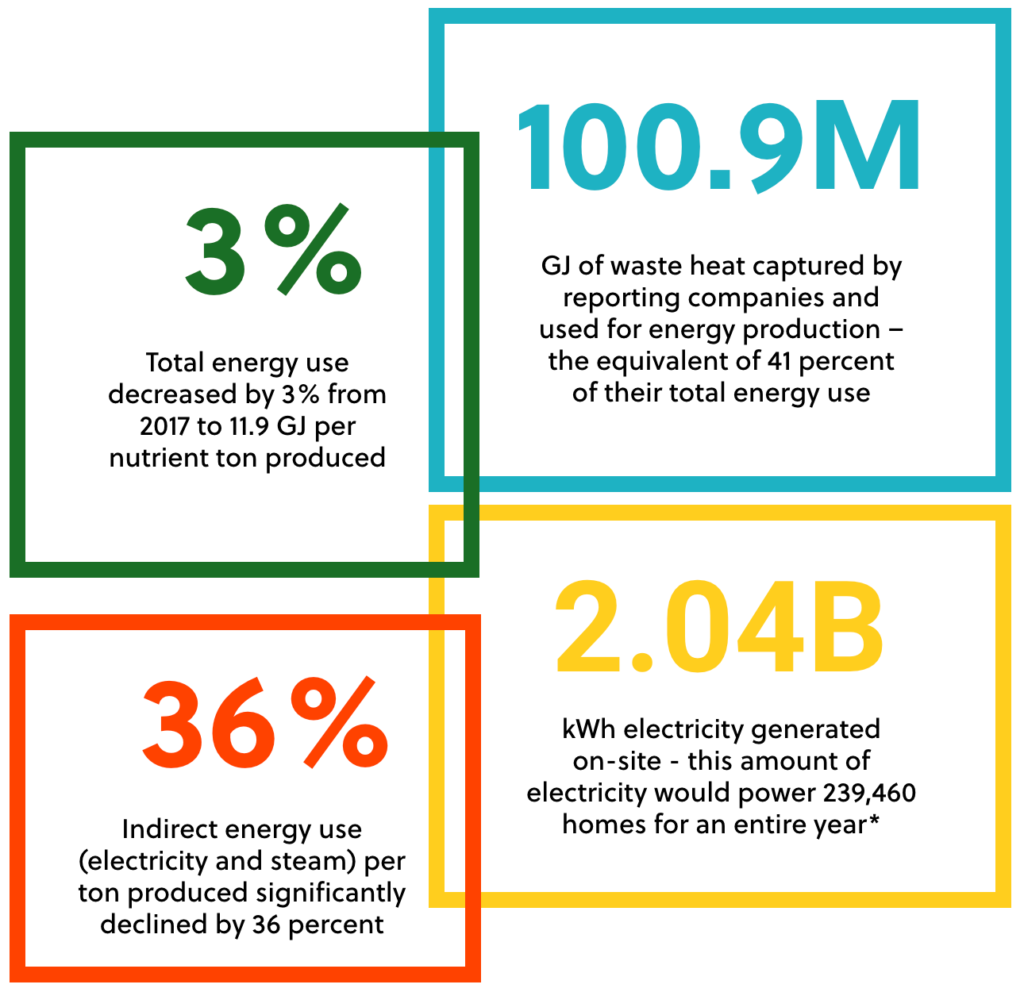

#7 Affordable and Clean Energy

Clean, abundant natural gas powers many of the industry’s production operations, and waste heat recapture technologies make facilities more efficient.

#9 Innovation and Infrastructure

Capital investments to advance innovation and improve infrastructure have positive impacts on safety, environmental, and energy performance.

#13 Climate Action

Practices are in place to capture and reuse CO2 emitted during fertilizer production, and on the farm, optimized fertilizer use to reduce nitrogen emissions is pursued.

Fertilizer and the United Nations Sustainable Development Goals

The United Nations’ 17 Sustainable Development Goals (SDGs) involve the work of governments, business, and citizens to end poverty and promote prosperity while protecting the planet. TFI and our members are actively contributing to the following SDGs.

The fertilizer industry supplies the nutrients needed to grow the crops that feed the world.

Sustainable water management practices and land reclamation are in place during fertilizer production, and on the farm, fertilizer best management practice awareness, research, and implementation is a priority to reduce environmental loss. The adoption of 4R fertilizer management practices is a priority to improving water quality.

Clean, abundant natural gas powers many of the industry’s production operations, and waste heat recapture technologies make facilities more efficient.

Practices are in place to capture and reuse CO2 emitted during fertilizer production, and on the farm, optimized fertilizer use to reduce nitrogen emissions is pursued.

FERTILIZER

FERTILIZER

ON THE FARM

ON THE FARM

UN GOALS: 2, 6, 13

TFI members seek to have all plant nutrients applied using the 4R Nutrient Stewardship framework using the right nutrient source at the right rate, the right time, and in the right place. The 4Rs reduce the loss of nutrients to the environment while also addressing sustainability concerns, such as improved profitability of the farm, improved water quality, and reduced loss of greenhouse gases. To accomplish this, the fertilizer industry must work together with a large group of partners, including TFI members, the Foundation for Agronomic Research, crop advisors, NGO stakeholders, industry partners, the academic community, and our farmer customers.

RIGHT SOURCE

RIGHT RATE

RIGHT TIME

RIGHT PLACE

UN GOALS: 2, 6, 13

TFI members seek to have all plant nutrients applied using the 4R Nutrient Stewardship framework using the right nutrient source at the right rate, the right time, and in the right place. The 4Rs reduce the loss of nutrients to the environment while also addressing sustainability concerns, such as improved profitability of the farm, improved water quality, and reduced loss of greenhouse gases. To accomplish this, the fertilizer industry must work together with a large group of partners, including TFI members, the Foundation for Agronomic Research, crop advisors, NGO stakeholders, industry partners, the academic community, and our farmer customers.

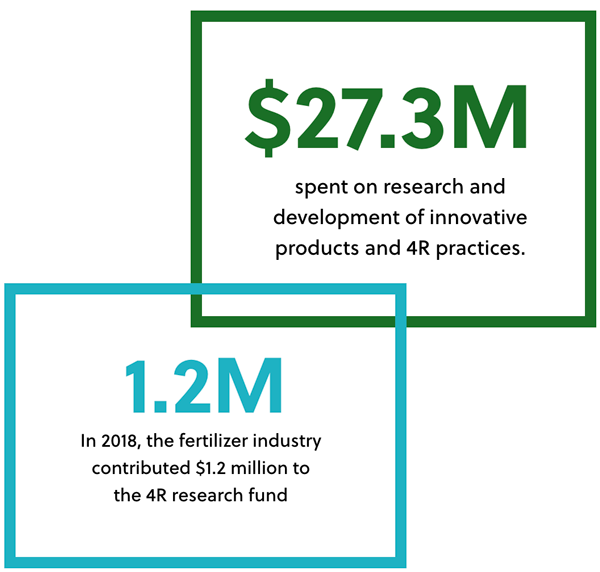

Research

Research investment leads to innovations and improved fertilizer products, practices, and technologies. Research also allows for the evaluation of 4R practices’ impact on crop yield and understanding their benefits for reducing fertilizer loss to the water and air.

Research

Research investment leads to innovations and improved fertilizer products, practices, and technologies. Research also allows for the evaluation of 4R practices’ impact on crop yield and understanding their benefits for reducing fertilizer loss to the water and air.

INDUSTRY VOICES

Water quality research demonstrates industry, academic partnership

Matt Helmers, professor, department of Agriculture and Biosystems Engineering; dean’s professor, college of Agriculture and Life Sciences; director, Iowa Nutrient Research Center

Matt Helmers leads a team who manages water quality research sites throughout Iowa. They work with farmers, stakeholders and Extension specialists across the region to examine ways to increase adoption of conservation practices and provide opportunities for people to learn more about conservation practices.

Working under a grant from the 4R Research Fund and the Foundation for Food and Agriculture Research, Helmers and his team are using eight drainage water quality research facilities in the Upper Midwest to examine the impacts of 4R nitrogen management on crop yield, greenhouse gas emissions, drainage water quality and soil health.

Helmers explains how projects such as this one and others funded by the 4R Research Fund address gaps in research. He also says this is an exemplary approach for academia and industry to work together.

Helmers adds the results from this type of research, combined with continued progress in precision agriculture provides unlimited potential to improve soil and crop performance.

Matt Helmers, professor, department of Agriculture and Biosystems Engineering; dean’s professor, college of Agriculture and Life Sciences; director, Iowa Nutrient Research Center

Water quality research demonstrates industry, academic partnership

Matt Helmers leads a team who manages water quality research sites throughout Iowa. They work with farmers, stakeholders and Extension specialists across the region to examine ways to increase adoption of conservation practices and provide opportunities for people to learn more about conservation practices.

Working under a grant from the 4R Research Fund and the Foundation for Food and Agriculture Research, Helmers and his team are using eight drainage water quality research facilities in the Upper Midwest to examine the impacts of 4R nitrogen management on crop yield, greenhouse gas emissions, drainage water quality and soil health.

Helmers explains how projects such as this one and others funded by the 4R Research Fund address gaps in research. He also says this is an exemplary approach for academia and industry to work together.

Helmers adds the results from this type of research, combined with continued progress in precision agriculture provides unlimited potential to improve soil and crop performance.

INDUSTRY VOICES

INDUSTRY VOICES

Incubator farms demonstrate ongoing quest for knowledge

Toby Goodroad, market development director, Yara North America Inc.

Yara is a global crop nutrition company that has been selling products and solutions since 1905. With more than 17,000 employees worldwide, the company focuses heavily on increasing knowledge in crop nutrition and environmental solutions. One way it does that is by investing to find real-world solutions to crop nutrition needs.

Toby Goodroad, market development director for Yara North America, shares the company’s vision of using incubator farms to create a culture of collaboration that leads to solutions that can be applied to multiple crops worldwide.

Investments in incubator farms and supporting research demonstrate the commitment Yara has to growers and dealer customers.

Toby Goodroad, market development director, Yara North America Inc.

Incubator farms demonstrate ongoing quest for knowledge

Yara is a global crop nutrition company that has been selling products and solutions since 1905. With more than 17,000 employees worldwide, the company focuses heavily on increasing knowledge in crop nutrition and environmental solutions. One way it does that is by investing to find real-world solutions to crop nutrition needs.

Toby Goodroad, market development director for Yara North America, shares the company’s vision of using incubator farms to create a culture of collaboration that leads to solutions that can be applied to multiple crops worldwide.

Investments in incubator farms and supporting research demonstrate the commitment Yara has to growers and dealer customers.

INDUSTRY VOICES

4R Partnerships

Partnerships are fundamental to ensuring all nutrients are applied using the 4Rs. Industry members partner with government and non-government organizations to extend resources and amplify outreach and implementation efforts.

Agribusiness Associations in multiple states

American Society of Agronomy Certified Crop Advisor Program

Association of Soil & Water Conservation Districts

Auburn University

Chesapeake Bay Foundation

Delaware-Maryland 4R Alliance

Ducks Unlimited

Farm Bureaus in multiple states

Field to Market

Florida Research Center for Agricultural Sustainability

Global Compact for Climate Smart Agriculture

Global Compact Network Canada

Illinois Nutrient Research and Education Council

IFA

Iowa Nutrient Research and Education Council

Iowa 4R Plus

Louisiana State University

Mid-Atlantic 4R Stewardship Association

Mississippi State University

Oregon State University

Pennsylvania 4R Alliance

Resources for the Future

The Nature Conservancy

Trees Forever

USDA Natural Resources Conservation Service

United Nations Sustainable Development Solutions Network

University of California-Merced

University of Central Florida

University of Florida

University of Georgia

University of Maryland

University of Wisconsin

USA Rice

World Business Council for Sustainable Development

INDUSTRY VOICES

Collaboration improves crop, water and wildlife habitat

Kyle Soileau, rice stewardship coordinator, Ducks Unlimited Wes Simon, rice grower

Putting 4R best management practices in place takes collaboration among farmers, industry, academia and industry allies. Working with the United States Department of Agriculture Natural Resources Conservation Service, The Mosaic Company and other financial partners, Ducks Unlimited partnered with the USA Rice Federation to improve nutrient management and provide habitat for waterfowl in rice-growing areas of the U.S.

Kyle Soileau is rice stewardship coordinator with Ducks Unlimited. Wes Simon is a fifth-generation farmer growing rice, soybeans and crawfish on 9,000 acres in southern Louisiana. Kyle and his team work with farmers on nutrient management plans, irrigation, water management and other practices that reduce input costs, improve the environment and bump the bottom line. USA Rice and the Simon family are working together to improve fertilizer management practices, water management and implement more precision ag technology. Their story is one of effective results.

The benefits are showing, Simon says. “The next generation is going to see the effects of the choices we make now. We see the positive changes that have happened on our farms and our neighbors’ farms. We’re all seeing the benefits of this partnership.”

Kyle Soileau, rice stewardship coordinator, Ducks Unlimited Wes Simon, rice grower

Collaboration improves crop, water and wildlife habitat

Putting 4R best management practices in place takes collaboration among farmers, industry, academia and industry allies. Working with the United States Department of Agriculture Natural Resources Conservation Service, The Mosaic Company and other financial partners, Ducks Unlimited partnered with the USA Rice Federation to improve nutrient management and provide habitat for waterfowl in rice-growing areas of the U.S.

Kyle Soileau is rice stewardship coordinator with Ducks Unlimited. Wes Simon is a fifth-generation farmer growing rice, soybeans and crawfish on 9,000 acres in southern Louisiana. Kyle and his team work with farmers on nutrient management plans, irrigation, water management and other practices that reduce input costs, improve the environment and bump the bottom line. USA Rice and the Simon family are working together to improve fertilizer management practices, water management and implement more precision ag technology. Their story is one of effective results.

The benefits are showing, Simon says. “The next generation is going to see the effects of the choices we make now. We see the positive changes that have happened on our farms and our neighbors’ farms. We’re all seeing the benefits of this partnership.”

INDUSTRY VOICES

INDUSTRY VOICES

Partnership with industry ally yields benefits

Adam Herges, sustainability agronomist, The Mosaic Company

The Mosaic Company is investing heavily in nutrient stewardship in a partnership with Ducks Unlimited and USA Rice. This work has resulted in cost-share incentives and educational outreach that have improved 4R practices on more than 140,000 acres of rice in the Mississippi valley since 2015. Rice growers focus nutritional practices on increasing yields and improvement the environmental outcomes on their operations.

Adam Herges is a sustainability agronomist with The Mosaic Company. He shares how this work is helping farmers in the U.S. and how it can help continue efficient production of rice worldwide. It’s important work, as rice is a major food staple to more than 3 billion people.

The continued expansion of these efforts bodes well for continued innovation in rice production in the U.S. and worldwide.

Adam Herges, sustainability agronomist, The Mosaic Company

Partnership with industry ally yields benefits

The Mosaic Company is investing heavily in nutrient stewardship in a partnership with Ducks Unlimited and USA Rice. This work has resulted in cost-share incentives and educational outreach that have improved 4R practices on more than 140,000 acres of rice in the Mississippi valley since 2015. Rice growers focus nutritional practices on increasing yields and improvement the environmental outcomes on their operations.

Adam Herges is a sustainability agronomist with The Mosaic Company. He shares how this work is helping farmers in the U.S. and how it can help continue efficient production of rice worldwide. It’s important work, as rice is a major food staple to more than 3 billion people.

The continued expansion of these efforts bodes well for continued innovation in rice production in the U.S. and worldwide.

INDUSTRY VOICES

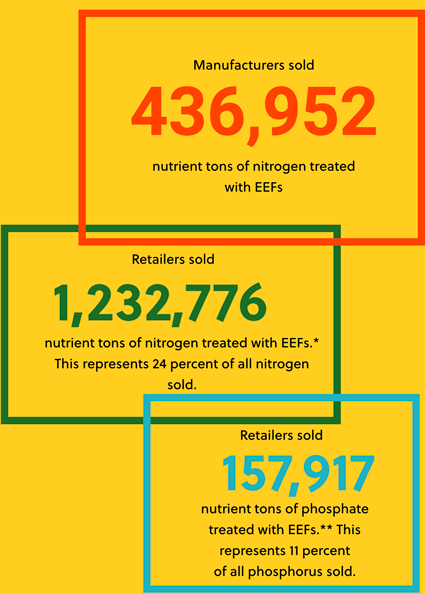

Enhanced Efficiency Fertilizers

Enhanced efficiency fertilizers (EEFs) are one of the tools farmers can use to improve nutrient uptake by the plant and reduce losses to the environment. EEFs are used in conjunction with both nitrogen and phosphorus fertilizers. In 2018, 21 percent of all nitrogen and phosphorus sold by retailers was treated with EEFs.

* This is an increase of 24 percent from 2017.

** This is a 6 percent increase from 2017.

INDUSTRY VOICES

Improved fertilizers deliver greater yield, lower environmental impact

Mark Goodwin, regional accounts manager, plant nutrition, Compass Minerals

Enhanced efficiency fertilizers (EEFs) use multiple technologies to help farmers incorporate more sustainable management practices. Compass Minerals is investing in on-farm research and in product development that help farmers use less phosphorous more efficiently than ever before. Its researchers are using greater understanding of how crop seedlings grow drive efficiency. Nu-traxx P-Plus is one example of a phosphorous product that works when a seedling needs it, where it needs it and is quickly used by plants

Mark Goodwin, regional accounts manager, plant nutrition with Compass Minerals, highlights the more surgical-like approaches to nutrition EEFs offer. He also provides insights to the ongoing investment Compass Minerals makes in its research farm near Kansas City, Missouri, USA.

Combining the latest plant nutrition research, plant genetics and precision ag technology are helping Compass Minerals develop products and practices that enable crops to efficiently use applied nutrients. This puts more returns on nutrition investments into farmers’ pockets.

Mark Goodwin, regional accounts manager, plant nutrition, Compass Minerals

Improved fertilizers deliver greater yield, lower environmental impact

Enhanced efficiency fertilizers (EEFs) use multiple technologies to help farmers incorporate more sustainable management practices. Compass Minerals is investing in on-farm research and in product development that help farmers use less phosphorous more efficiently than ever before. Its researchers are using greater understanding of how crop seedlings grow drive efficiency. Nu-traxx P-Plus is one example of a phosphorous product that works when a seedling needs it, where it needs it and is quickly used by plants

Mark Goodwin, regional accounts manager, plant nutrition with Compass Minerals, highlights the more surgical-like approaches to nutrition EEFs offer. He also provides insights to the ongoing investment Compass Minerals makes in its research farm near Kansas City, Missouri, USA.

Combining the latest plant nutrition research, plant genetics and precision ag technology are helping Compass Minerals develop products and practices that enable crops to efficiently use applied nutrients. This puts more returns on nutrition investments into farmers’ pockets.

INDUSTRY VOICES

Agronomists – A Trusted Resource

Farmers consistently rate crop advisers and agronomists as their most trusted source of information when making fertilizer decisions. These agronomic professionals help farmers implement 4R-based nutrient management plans and adopt precision agriculture technologies.

Certified Crop Advisers (CCAs) and Certified Professional Agronomists (CPAgs) are professional agronomists who have met rigorous standards prescribed by the American Society of Agronomy. The CCA and CPAg certification assures farmers their adviser is equipped to help them make sound fertilizer decisions.

4Rs at Work

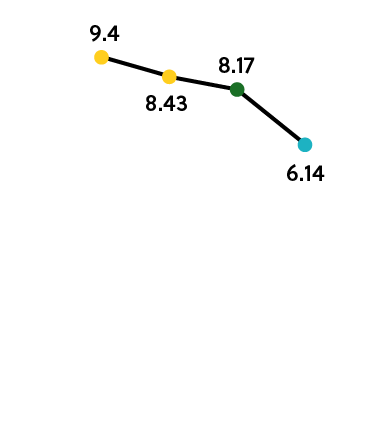

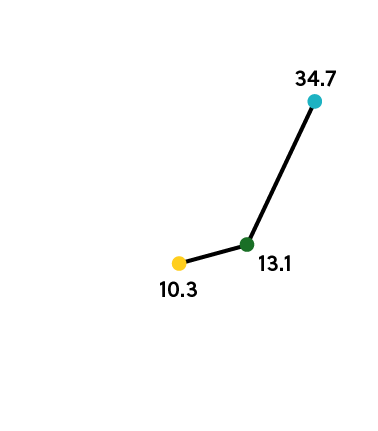

Cost is a major factor to consider when deciding whether to implement new practices in a field. 4R fertilizer management practices are no exception. TFI gathered data from farmers who have implemented 4R practices to measure the environmental and economic benefits to their farms.

4R Practice Benefits for a Strip-Till Corn Farmer in Illinois

4R Practice Benefits for a Strip-Till Corn Farmer in Illinois

Basic

Intermediate

Advanced

For example, a farmer growing strip-till managed corn in Illinois who went from basic to advanced 4R practices reduced his CO2 emissions by 34.7 percent over the course of four years. Additionally, cost per acre decreased by more than $60 due to lower fertilizer costs associated with variable rate applications and decreased labor and equipment costs for strip till applications of anhydrous ammonia versus full, custom application of anhydrous ammonia.

But don’t take our word for it. More case studies are available at

But don’t take our word for it. More case studies are available at

INDUSTRY VOICES

Partnership helps deliver actionable information farmers can apply

Amber Radatz, co-director Discovery Farms, University of Wisconsin

The University of Wisconsin is a great example of how partnerships with academia, Extension and TFI can expand. Matt Ruark, professor of soil fertility and nutrient management, has partnered with TFI on several initiatives. It was only natural than when TFI wanted to survey Wisconsin farmers about how they’ve improved fertilizer management practices that the university be involved.

So, TFI turned to Amber Radatz, co-director of Discovery Farms at the university to work with Wisconsin farmers to quantify the changes they’ve made to improve phosphorous and nitrogen management practices. Radatz and her team are now compiling results of the surveys that will include environmental outcomes, as well as positive financial results for farms that improved practices.

Radatz says that partnerships such as these helps advance information more quickly than could be done otherwise, thus allowing farmers to incorporate advanced farming practices as quickly as possible.

Amber Radatz, co-director Discovery Farms, University of Wisconsin

Partnership helps deliver actionable information farmers can apply

The University of Wisconsin is a great example of how partnerships with academia, Extension and TFI can expand. Matt Ruark, professor of soil fertility and nutrient management, has partnered with TFI on several initiatives. It was only natural than when TFI wanted to survey Wisconsin farmers about how they’ve improved fertilizer management practices that the university be involved.

So, TFI turned to Amber Radatz, co-director of Discovery Farms at the university to work with Wisconsin farmers to quantify the changes they’ve made to improve phosphorous and nitrogen management practices. Radatz and her team are now compiling results of the surveys that will include environmental outcomes, as well as positive financial results for farms that improved practices.

Radatz says that partnerships such as these helps advance information more quickly than could be done otherwise, thus allowing farmers to incorporate advanced farming practices as quickly as possible.

INDUSTRY VOICES

people &

people &

COMMUNITIES

COMMUNITIES

UN GOAL: 9

UN GOAL: 9

With a mission to feed the planet, the fertilizer industry has always been about more than just plant nutrients. People and communities are the top priority, and the industry invests heavily in worker and community safety.

Employee Safety

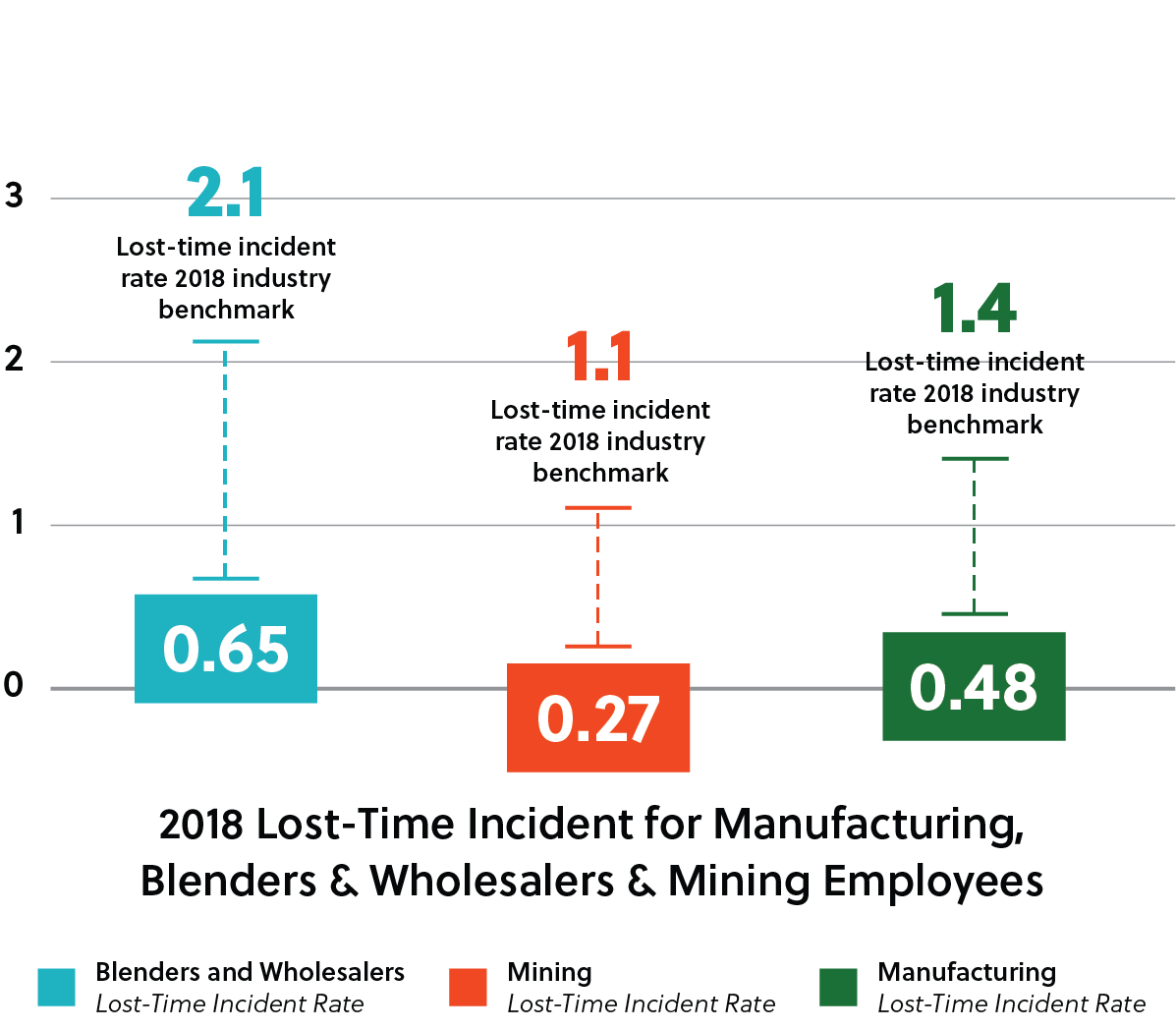

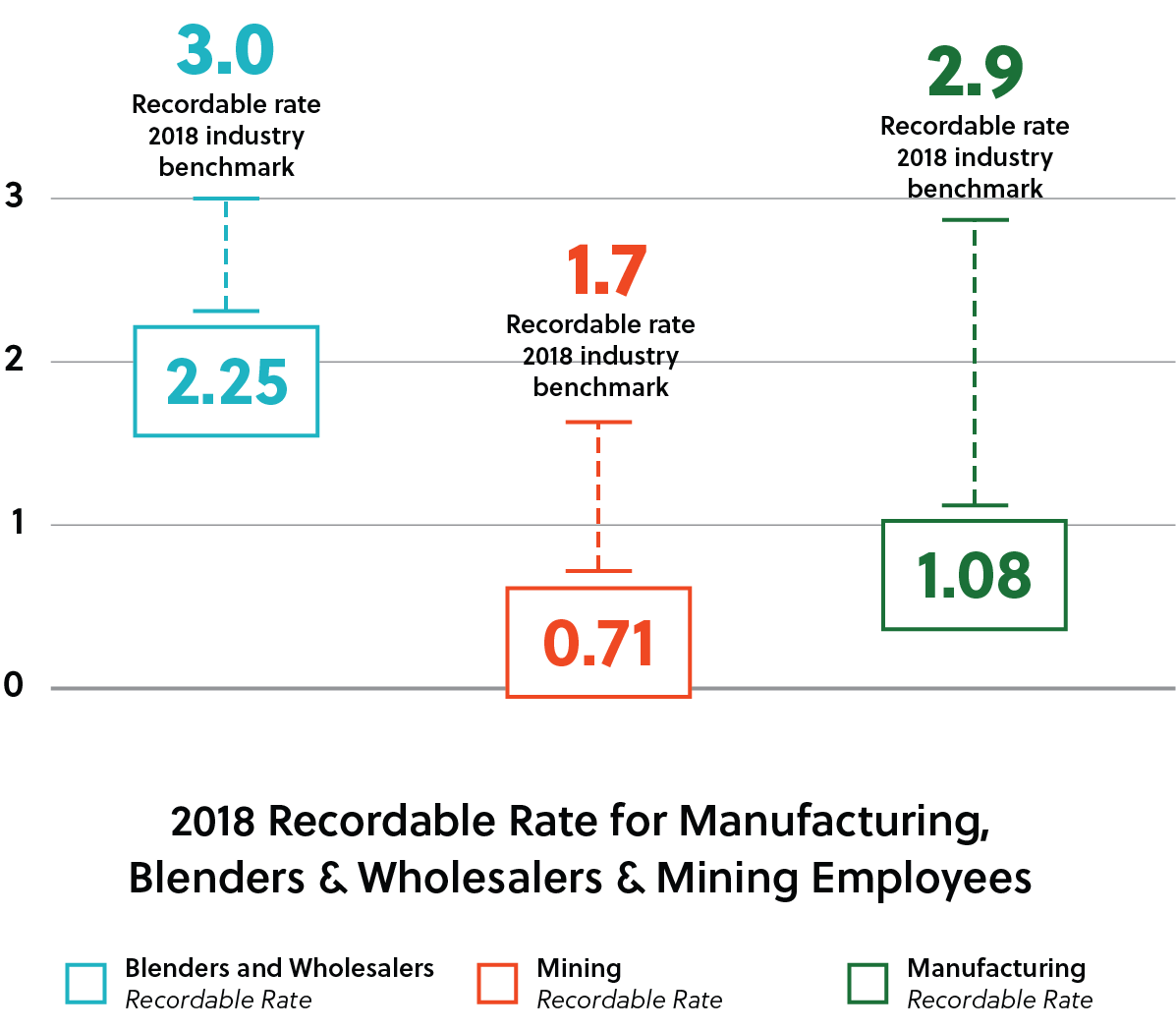

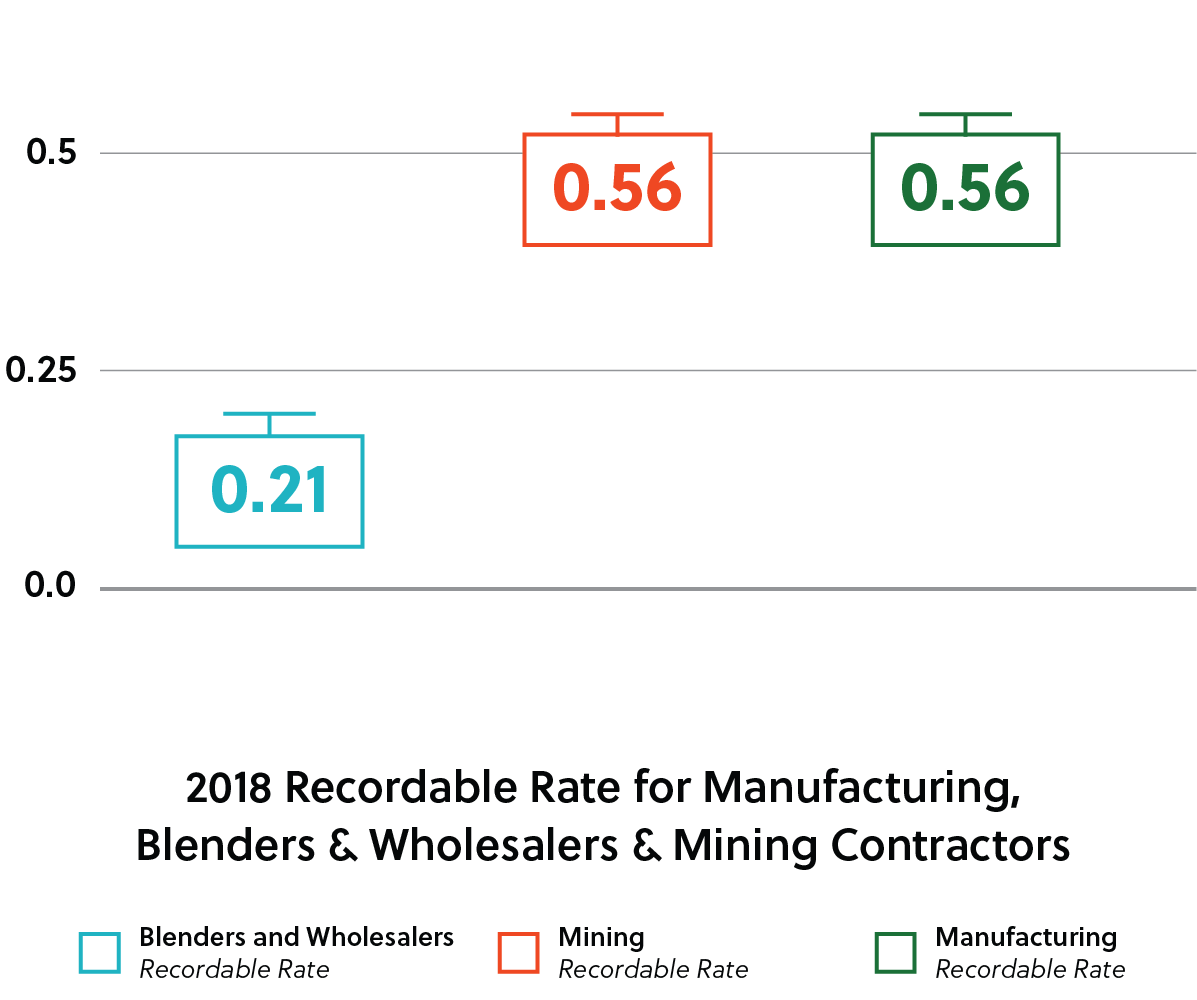

In 2018, the lost-time incident rate was the lowest recorded across the fertilizer supply chain and the recordable rate was the second-lowest recorded since TFI began collecting data in 2013.

Safety performance among participating TFI member companies continued to outperform industry peers when compared to data released in November 2019 by the U.S. Bureau of Labor Statistics.

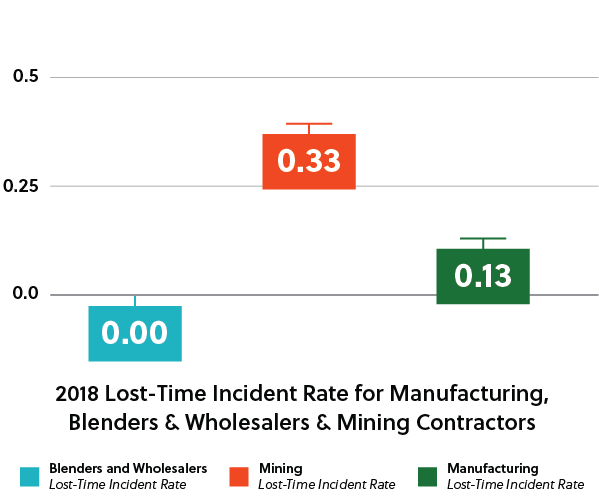

For the first time in 2018, TFI is able to report on the safety data for contractors employed by the fertilizer industry. As a whole, the lost-time incident rates and recordable rates fall below the industry averages.

INDUSTRY VOICES

Safety pays off for manufacturers and industry

Mike Hamilton, business director for Plant Nutrients, AdvanSix

Safety is a job that belongs to every employee in the company. AdvanSix leadership does its best to ensure safety is a strong part of its operational culture. It is important that employees are confident that they will leave a facility as well as they are when they walk in. Community members must have confidence in day-to-day facility operations. A strong safety culture also ensures a well-run operation.

Mike Hamilton, business director for Plant Nutrients with AdvanSix, explains how employees, community leaders, industry peers and customers all benefit from operational safety.

Mike Hamilton, business director for Plant Nutrients, AdvanSix

Safety pays off for manufacturers and industry

Safety is a job that belongs to every employee in the company. AdvanSix leadership does its best to ensure safety is a strong part of its operational culture. It is important that employees are confident that they will leave a facility as well as they are when they walk in. Community members must have confidence in day-to-day facility operations. A strong safety culture also ensures a well-run operation.

Mike Hamilton, business director for Plant Nutrients with AdvanSix, explains how employees, community leaders, industry peers and customers all benefit from operational safety.

INDUSTRY VOICES

INDUSTRY VOICES

Safety critical to operations, employees, community

Alec Rusche, environmental health and safety manager, TradeMark

A one-team mindset drives the safety culture at TradeMark. From management to employees, this spirit of teamwork encourages employees at all levels to openly discuss EHS practices. This has created an atmosphere where the TradeMark teams aspires to be an example within the industry.

TradeMark’s environmental health and safety manager is Alec Rusche. He shares that the TradeMark team doesn’t take the responsibility for being a good community steward lightly. In addition to delivering quality products to customers, TradeMark employees insist on practicing the most stringent safety protocols.

It works. TradeMark has gone more than 5,100 days without lost time. Rusche explains how.

TradeMark’s well-rounded safety programs will continue to pay off for years to come.

Alec Rusche, environmental health and safety manager, TradeMark

Safety critical to operations, employees, community

A one-team mindset drives the safety culture at TradeMark. From management to employees, this spirit of teamwork encourages employees at all levels to openly discuss EHS practices. This has created an atmosphere where the TradeMark teams aspires to be an example within the industry.

TradeMark’s environmental health and safety manager is Alec Rusche. He shares that the TradeMark team doesn’t take the responsibility for being a good community steward lightly. In addition to delivering quality products to customers, TradeMark employees insist on practicing the most stringent safety protocols.

It works. TradeMark has gone more than 5,100 days without lost time. Rusche explains how.

TradeMark’s well-rounded safety programs will continue to pay off for years to come.

INDUSTRY VOICES

Community Safety

The fertilizer industry is a part of communities, large and small, across the country. To keep their communities safe, the industry invests in safety training to protect employees, first responders, and surrounding communities. Training local emergency responders how to react to and mitigate accidents involving different types of chemicals is an investment in the safety of the entire community.

ResponsibleAg is a nonprofit organization founded by companies in the fertilizer industry to assist agribusinesses as they seek to comply with federal rules regarding the safe handling and storage of fertilizer products. The organization provides participating businesses a federal regulatory compliance assessment, relates recommendations for corrective action where needed, and offers a robust suite of resources to assist in this regard.

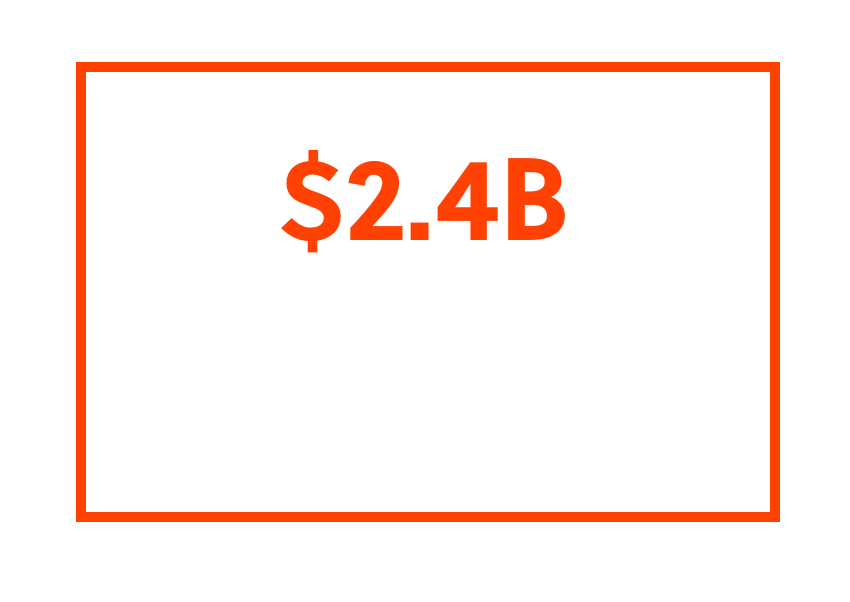

Capital Investments

Capital investments help the industry meet sustainability goals by increasing production efficiencies, reducing energy and water use, reducing greenhouse gas emissions, and strengthening the U.S. economy.

Capital investments are equally important to the fertilizer retail sector. Investments in technology and tools to protect the environment help retailers assist farmers in applying 4R Nutrient Stewardship in their nutrient management plans. As stated earlier, the industry spent $27.3 million in 2018 on research and development towards innovative products and 4R nutrient stewardship practices.

Employee Investments

If there is one thing that truly makes the fertilizer industry successful, it’s the employees. Every day, hard-working men and women spend countless hours, 24/7, to keep production plants running, get fertilizer product to where it needs to be, and provide trusted advice to farmers on how best to apply these essential nutrients. The modern fertilizer industry is rooted in science and relies on highly trained professions. Read more about careers in the fertilizer industry.

ENERGY &

ENERGY &

ENVIRONMENT

ENVIRONMENT

UN GOALS: 6, 7, 9, 13

The production of fertilizer comes with a significant natural resources cost, such as natural gas, water, and land. However, TFI members have made significant achievements since data collection began on this report to do more with fewer resources.

As the total number of companies that participate in this report changes, so does the quantity of reported natural resources used. For clarity, this report will focus on normalized numbers or the amount of resources needed to produce one ton of fertilizer.

UN GOALS: 6, 7, 9, 13

The production of fertilizer comes with a significant natural resources cost, such as natural gas, water, and land. However, TFI members have made significant achievements since data collection began on this report to do more with fewer resources.

As the total number of companies that participate in this report changes, so does the quantity of reported natural resources used. For clarity, this report will focus on normalized numbers or the amount of resources needed to produce one ton of fertilizer.

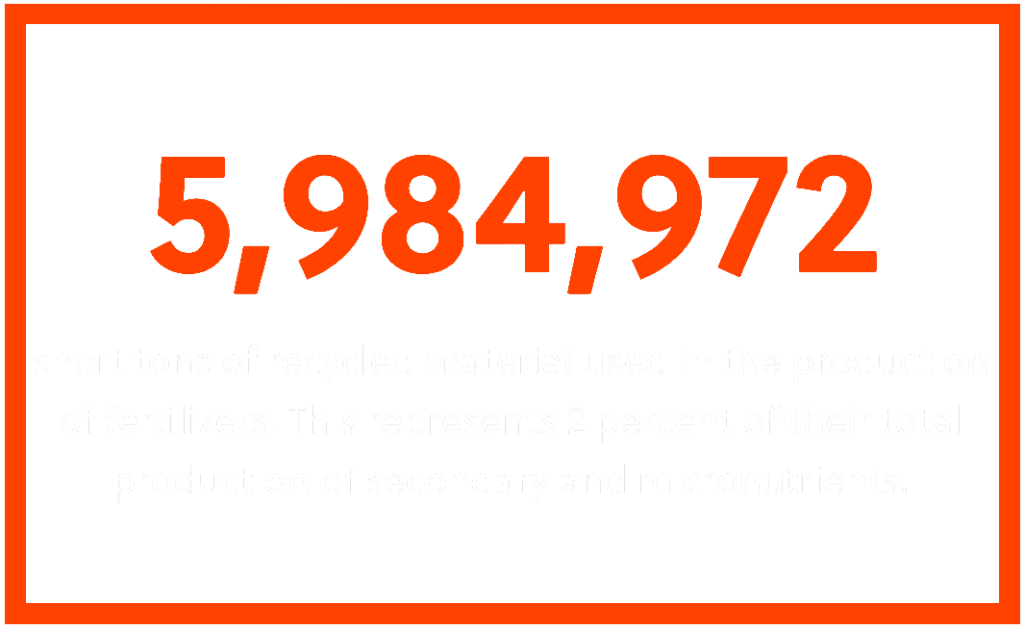

Recycled Materials

Many secondary and micronutrients are produced as co-products or from byproducts from various industries. For example, ammonium sulfate is produced during the nylon manufacturing process. Additionally, other fertilizer products are made from human or animal waste materials. In other cases, sulfur is recovered from the manufacturing process and used to produce phosphoric acid and steam and electricity for energy.

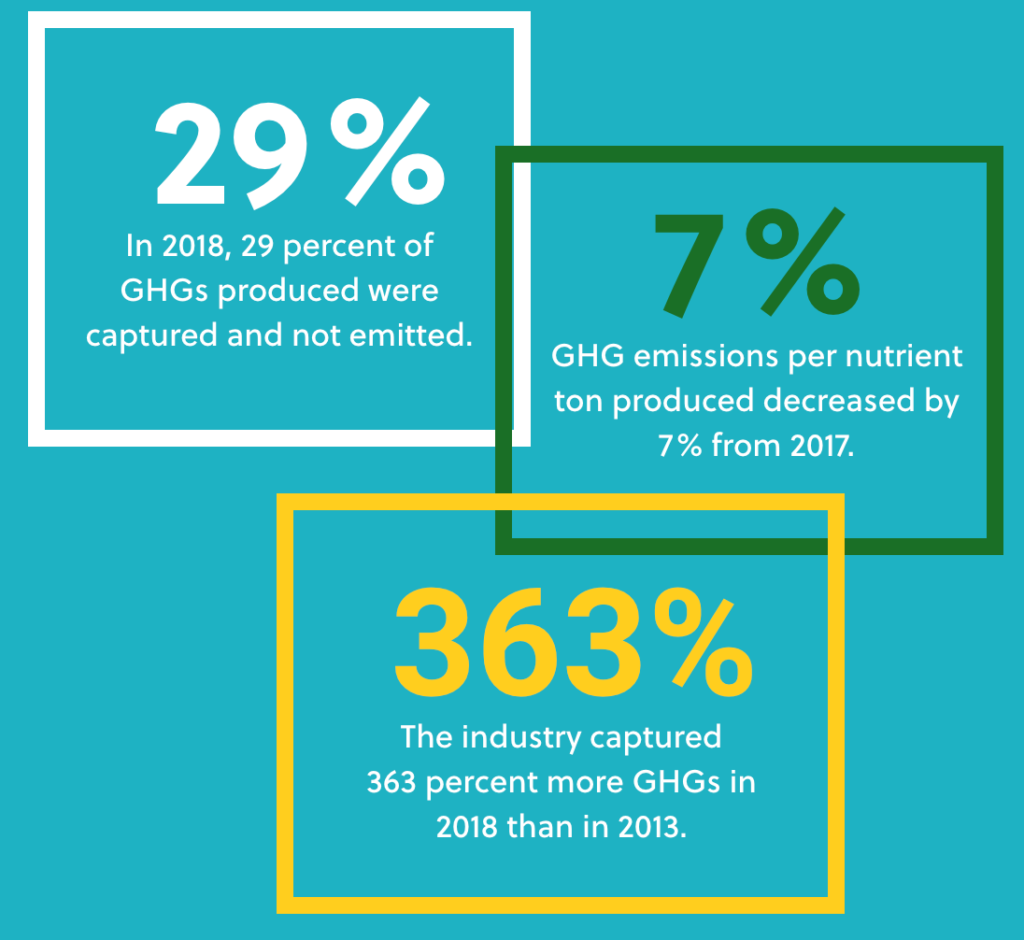

Greenhouse Gas Emissions

Minimizing greenhouse gas (GHG) emissions is a priority for companies in the fertilizer industry. High purity carbon dioxide (CO2) is a byproduct of ammonia production, but the industry captures it and is able to reuse it in the production of downstream nitrogen fertilizers. Captured CO2 is also sold as a byproduct for other industrial uses, such as enhanced oil recovery and the carbonization of soft drinks.

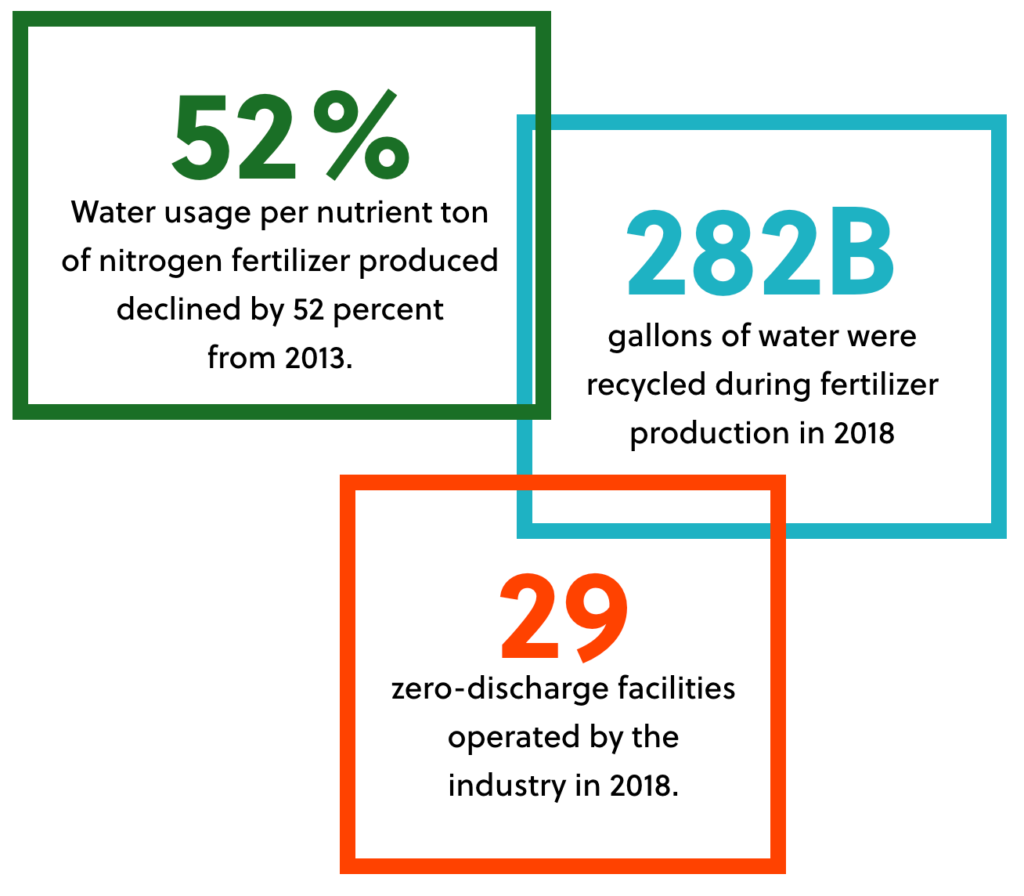

Water

Sustainable water use is a key element in the industry’s conservation efforts. Water is a significant resource in the production of phosphate and potash fertilizers, and to a lesser extent for nitrogen. Many fertilizer manufacturers have set water efficiency and zero-discharge goals for their operations. These goals are achieved through the use of recycled and reclaimed water. Recycled water refers to water demand an organization satisfies by reusing water during the production cycle instead of withdrawing additional water. Reclaimed water is wastewater used from third-party sources that offsets water that would otherwise be drawn from other sources.

INDUSTRY VOICES

Reclamation efforts provide amazing flora and fauna habitat

Jessica Solis, reclamation supervisor, The Mosaic Company

Reclaiming mines and accompanying stream re-creation techniques have progressed greatly in the last 20 years. Miners, engineers, fluvial geomorphologists and other professionals continue to make reclamation successes that result in great wildlife habitats, improve communities and ensure mined land is returned to a useful state.

Jessica Solis has worked with The Mosaic Company for 14 years. She is now a reclamation supervisor and handles the day-to-day reclamation, including the earthwork and planting of previously mined, reclaimed areas for the company’s south pasture mines. She details the years-long progress that is being made, how monitoring ensures reclamation efforts work and how creating habitat for all types of life pay off.

It takes teamwork to get mined ground back in shape. Thanks to The Mosaic Company and its partners, they’re putting things back better than they were before mining took place.

Jessica Solis, reclamation supervisor, The Mosaic Company

Reclamation efforts provide amazing flora and fauna habitat

Reclaiming mines and accompanying stream re-creation techniques have progressed greatly in the last 20 years. Miners, engineers, fluvial geomorphologists and other professionals continue to make reclamation successes that result in great wildlife habitats, improve communities and ensure mined land is returned to a useful state.

Jessica Solis has worked with The Mosaic Company for 14 years. She is now a reclamation supervisor and handles the day-to-day reclamation, including the earthwork and planting of previously mined, reclaimed areas for the company’s south pasture mines. She details the years-long progress that is being made, how monitoring ensures reclamation efforts work and how creating habitat for all types of life pay off.

It takes teamwork to get mined ground back in shape. Thanks to The Mosaic Company and its partners, they’re putting things back better than they were before mining took place.

INDUSTRY VOICES

TRANSPORTATION

TRANSPORTATION

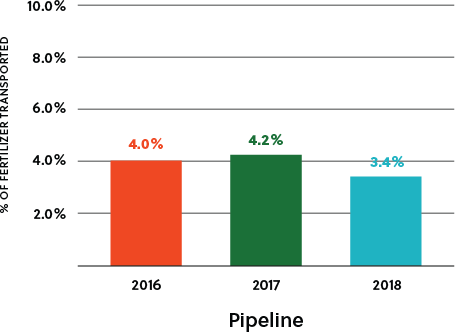

UN GOALS: 6, 7, 9, 13

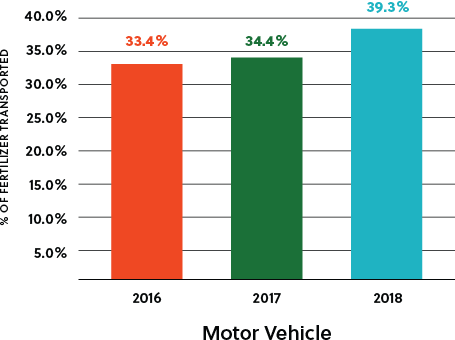

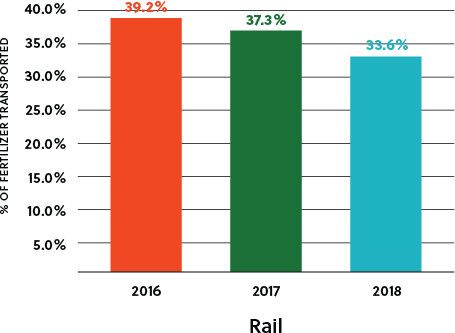

Change in mode of Fertilizer transportation 2016 – 2018

UN GOALS: 6, 7, 9, 13

Farmers rely on the timely transportation of fertilizer when and where they need it. This requires a complex transportation logistics puzzle as fertilizer moves from production facility to storage warehouses to retail facilities and finally to the farm. The industry relies on various modes to achieve this: rail, trucking, barges, and pipelines. All modes are crucial. A balanced transportation network is essential to ensure fertilizer reaches growers when they need it.

Change in mode of Fertilizer transportation 2016 – 2018

INDUSTRY VOICES

Staying abreast of transportation issues ensures timely product delivery

Todd Minnihan, vice president, crop nutrients, Winfield United

Land O’Lakes buys products that are delivered by almost all means of transportation, including barge, rail and truck. It owns its own trucking company and has anhydrous ammonia trailers and liquid fertilizer trailers. The cooperative also owns a fleet of chemical tankers. It invests in the transportation industry to provide good service to customers and make sure products are delivered on time. It continues to be a growing part of the company’s value proposition.

Todd Minnihan, Winfield United’s vice president, crop nutrients offers perspective on why the sensitivity of fertilizer to freight costs and how it affects customers.

These efforts, Minnihan says, complement Winfield United’s work in all programs, including its sustainable farming efforts. Just like the 4Rs, he says once farmers see the environmental and economic benefits of it, the adoption rate shoots up.

Todd Minnihan, vice president, crop nutrients, Winfield United

Staying abreast of transportation issues ensures timely product delivery

Land O’Lakes buys products that are delivered by almost all means of transportation, including barge, rail and truck. It owns its own trucking company and has anhydrous ammonia trailers and liquid fertilizer trailers. The cooperative also owns a fleet of chemical tankers. It invests in the transportation industry to provide good service to customers and make sure products are delivered on time. It continues to be a growing part of the company’s value proposition.

Todd Minnihan, Winfield United’s vice president, crop nutrients offers perspective on why the sensitivity of fertilizer to freight costs and how it affects customers.

These efforts, Minnihan says, complement Winfield United’s work in all programs, including its sustainable farming efforts. Just like the 4Rs, he says once farmers see the environmental and economic benefits of it, the adoption rate shoots up.

INDUSTRY VOICES

Fertilizer is on the move all year round. Production facilities operate 365, 24/7, meaning fertilizer needs to be transported throughout the year.

2018 Seasonal Movement of Fertilizer

SUSTAINABILITY

PERFORMANCE

SUSTAINABILITY

PERFORMANCE

INDICATORS

INDICATORS

The State of the Fertilizer Industry Report is an effort to amplify the industry’s voices on issues that impact fertilizer manufacturing, transportation, and use. This report is a mechanism for gathering data on the social, economic, and environmental impacts of members within the fertilizer industry. The aggregated data summarized in the annual report is then used to support TFI’s various advocacy and outreach programs.

Participation in the report is voluntary, and includes data provided by TFI member companies doing business in the United States. TFI contracted with Environmental Resources Management (ERM) to facilitate the development and reporting of identified metrics. ERM maintains third-party confidentiality while collecting, reviewing, and aggregating the data collected from participating companies.